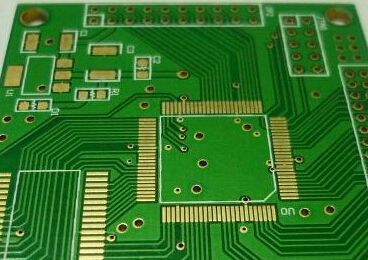

RF circuit PCB design process

Because the use of Protel99SE software is different from Protel 98 and other software, this article first briefly discusses the process of PCB design using Protel99SE software.

1 Since Protel99SE adopts the project (PROJECT) database mode management, this is implicit under Windows 99, so a database file should be established to manage the circuit schematic and PCB layout.

(2) In the design of the schematic diagram, in order to realize the network connection, the components used in the principle design must exist in the component library, otherwise the required components must coexist in the SCHLIB storage file, and then only need to be called from the component library The components are connected according to the designed circuit diagram.

(3) After the schematic design is completed, a netlist can be formed for PCB design.

4PCB design

Determination of PCB shape and size. Determine the shape and size of the PCB according to the position of the designed PCB in the product, the size and shape of the space, and the coordination with other components. The shape of the PCB is drawn by the PLACETRACK command on the MECHICALLAYER layer.

b. According to the requirements of SMT, make positioning holes, eyes, reference points, etc. on the PCB.

c. Manufacture of components. If you need to use some special components that do not exist in the component library, you need to generate the components before layout. The production process of Protel99SE components is relatively simple. After selecting the "MAKELIBRARY" command in the "Design" menu, enter the component creation window, and then you can select the "NEWCOMPONENT" command in the "Tool" menu to design the component. At this time, only need to draw the corresponding pad at a certain position according to the shape and size of the actual component in the TOPLAYER layer, and edit it into the required pad (including pad shape, size, inner diameter size and angle, etc., in addition to The corresponding pin name of the pad should be marked). In addition, the corresponding pad pin name should be marked, and then use the PLACETRACK command to draw the maximum shape of the component on the TOPOVERLAYER layer, and store the component name in the component library.

After the components are made, layout and wiring are carried out. These two parts are discussed in detail below.

(The network formed by the schematic diagram can be compared with the network formed by the PCB) After the above process is completed, an inspection must be performed. On the one hand, it includes the inspection of the circuit principle, on the other hand, it also needs to check the matching and assembly problems between each other. The circuit principle can be checked manually or automatically by the network (the network formed by the schematic diagram can be compared with the network formed by the PCB).

f. After the inspection, the file is archived and output. In Protel99SE, you must use the "export" command in the "file" option to store the file in the specified path and file (the "IMPORT" command transfers a file to Protel99SE). Note: In the "file" option in Protel99SE, "SAVECOPYAS." After executing the command, the selected file name cannot be seen in Windows 98, so the file is not visible in the Explorer. This is similar to the "file" in Protel98. The functions are not exactly the same.

Address:3-401, Dahong Technology Innovation Park, Xinyu Road, Shajing Street, Baoan District, Shenzhen

Q Q:172750477