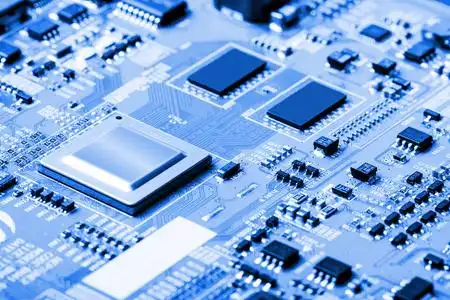

Even with modern SMT equipment and automated inspection, PCB assembly defects remain one of the leading causes of product delays, rework, and field failures. Most PCBA defects are not random—they are the result of design choices, process control, material handling, and inspection gaps. This guide reviews the most common PCB assembly defects and explains how to prevent them in real production.

Why PCB Assembly Defects Matter

A single solder-related defect can compromise electrical performance, reduce product lifetime, or cause intermittent failures that are difficult to diagnose. In volume production, even a small defect rate can translate into significant cost through rework, scrap, or customer returns.

Understanding defect mechanisms early—especially during prototype and pilot builds—is one of the most effective ways to improve long-term PCBA quality.

::contentReference[oaicite:0]{index=0}1) Solder Bridging

What It Is

Solder bridging occurs when excess solder connects adjacent pads or component leads, creating unintended electrical shorts.

Common Causes

Excess solder paste volume

Insufficient pad-to-pad spacing

Stencil misalignment or wear

Improper reflow profile

Prevention Methods

Optimize stencil thickness and aperture design

Follow IPC-recommended land patterns

Maintain accurate paste printing alignment

Use AOI to detect bridges early

2) Tombstoning (Chip Lift)

What It Is

Tombstoning occurs when one end of a small passive component lifts off the pad during reflow, leaving the component standing upright.

Common Causes

Uneven solder wetting between pads

Unbalanced pad geometry

Asymmetric thermal profile

Excessively small components (0201, 01005)

Prevention Methods

Use symmetric pad designs

Balance copper distribution near small passives

Optimize reflow soak and ramp rates

Avoid ultra-small passives unless required

3) Cold Solder Joints / Insufficient Wetting

What It Is

Cold solder joints appear dull, grainy, or cracked and may have poor mechanical and electrical connection. These joints are a common source of intermittent failures.

Common Causes

Low peak reflow temperature

Oxidized pads or component leads

Expired or contaminated solder paste

Improper flux activation

Prevention Methods

Verify reflow profile reaches proper liquidus temperature

Control PCB and component storage conditions

Use fresh, properly handled solder paste

Inspect joints with AOI and manual review

4) BGA / QFN Solder Voids

What It Is

Voids are trapped gas pockets within a solder joint, often hidden under BGA or bottom-terminated components. Excessive voiding can affect thermal and electrical performance.

Common Causes

Improper solder paste formulation

Inadequate reflow profile

Via-in-pad without proper filling

Moisture outgassing

Prevention Methods

Optimize stencil aperture design for BGAs

Use filled and planarized via-in-pad where required

Control component moisture sensitivity levels (MSL)

Verify joints using X-ray inspection

5) Component Misalignment or Shift

What It Is

Components may shift, rotate, or skew during placement or reflow, leading to poor solder joints or functional issues.

Common Causes

Incorrect pick-and-place programming

Inaccurate centroid data

Excess solder paste or paste slumping

Board warpage during reflow

Prevention Methods

Verify centroid data and rotation conventions

Control paste volume and viscosity

Use proper panel support to reduce warpage

Perform first-article inspection

6) Through-Hole Solder Defects

Common Issues

Insufficient hole fill

Excess solder and icicles

Cold joints on high-thermal-mass pins

Prevention Methods

Optimize wave or selective solder parameters

Ensure proper preheating of thick boards

Design adequate annular ring and hole size

7) Missing or Incorrect Components

What It Is

Incorrect component placement or missing parts can occur due to feeder errors, BOM mismatches, or sourcing substitutions.

Prevention Methods

Use barcode-based feeder verification

Maintain strict BOM and revision control

Leverage AOI and ICT for detection

Design-Level Actions That Prevent Assembly Defects

Follow IPC-recommended footprints

Provide clear polarity and pin-1 markings

Maintain consistent component orientation

Avoid unnecessary fine-pitch or exotic packages

Review designs with PCBA manufacturers before release

Conclusion

Most PCB assembly defects are preventable. By understanding their root causes and addressing them through good design practices, controlled processes, and appropriate inspection, manufacturers can significantly improve yield and product reliability. Early defect awareness—especially during prototype and pilot runs—pays long-term dividends in production stability and customer satisfaction.

FAQ

Which PCB assembly defect is most common?

Solder-related defects such as bridging, insufficient wetting, and tombstoning are among the most common, especially in dense SMT designs.

Can AOI detect all PCB assembly defects?

AOI is excellent for visible defects, but hidden joints under BGA or QFN packages require X-ray inspection for full coverage.

Do tighter layouts always increase defect risk?

Not always, but aggressive miniaturization reduces process margin. Careful footprint design, reflow profiling, and inspection become more critical as density increases.